Essential Guide to Choosing the Right Industrial Hydraulic Repair Services for Your Machinery

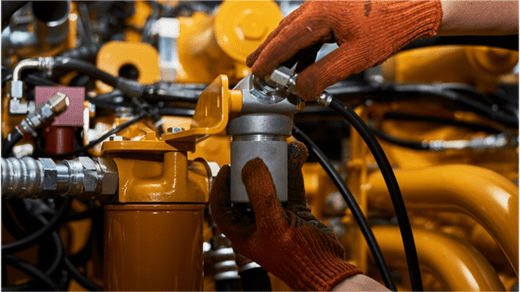

When it comes to industrial machinery, the reliability and efficiency of hydraulic systems are crucial for maintaining operational performance. However, like any mechanical system, these hydraulic systems can face wear and tear, leading to performance issues. In such cases, selecting the right industrial hydraulic repair services becomes a vital decision that impacts productivity, safety, and overall operational costs. This guide will walk you through the essential considerations for choosing the right industrial hydraulic repair service for your machinery.

1. Understanding the Importance of Industrial Hydraulic Repair

Hydraulic systems are used in a wide range of industrial applications, from construction equipment to manufacturing machinery. These systems rely on hydraulic fluid to transmit power and ensure precise motion control. When a hydraulic system breaks down, it can result in downtime, reduced efficiency, and potentially costly repairs if not addressed promptly. Professional Industrial Hydraulic Repair services are essential for diagnosing and fixing issues, restoring machinery to its optimal condition, and ensuring long-term performance.

2. Look for Expertise and Experience

One of the first factors to consider when choosing an industrial hydraulic repair service is the level of expertise and experience they offer. Hydraulic systems can be complex, requiring technicians with in-depth knowledge of the specific equipment and components involved.

- Specialized Knowledge: Ensure that the service provider specializes in hydraulic systems and has experience with the type of machinery you use.

- Industry Experience: The longer a company has been providing hydraulic repair services, the more likely they are to have a thorough understanding of common problems and effective solutions.

3. Evaluate Their Range of Services

A good industrial hydraulic repair service should offer a wide range of services to cater to the different needs of hydraulic systems. Some of the key services you should expect include:

- Hydraulic Pump Repair and Replacement: Hydraulic pumps are at the heart of most systems. A reputable repair service should be capable of diagnosing pump failure, conducting repairs, or recommending replacements if needed.

- Cylinder Repair: If the hydraulic cylinders on your equipment are leaking or malfunctioning, they should be able to repair or replace seals and restore full functionality.

- Hydraulic System Diagnostics: The repair service should offer thorough diagnostic testing to pinpoint the exact issues, preventing unnecessary replacements or repairs.

- Preventive Maintenance: To avoid future breakdowns, the repair service should provide regular maintenance options that help extend the lifespan of your hydraulic systems.

4. Check for Quality and Reputation

A service provider’s reputation speaks volumes about the quality of their work. When choosing an industrial hydraulic repair service, consider the following:

- Client Testimonials and Reviews: Look for feedback from other customers who have used their services. Positive reviews and testimonials can provide insight into their reliability, professionalism, and expertise.

- Certifications and Accreditations: Look for certifications from reputable organizations, such as the Hydraulic Industry Forum (HIF) or the International Fluid Power Society (IFPS). These certifications demonstrate a commitment to high standards and continuous improvement.

- Warranty and Guarantees: A good hydraulic repair service should stand by their work. Check if they offer warranties or guarantees on repairs and replacements to ensure peace of mind.

5. Consider Response Time and Availability

In the industrial sector, downtime is costly, and machinery failures often happen at inconvenient times. When selecting a repair service, it’s important to consider their availability and response time.

- 24/7 Availability: Emergencies can happen at any time, so choose a repair service that offers 24/7 support, especially if your operations run around the clock.

- Fast Response Time: The quicker the repair service can respond, the less downtime you will experience. A prompt response is particularly important in situations where your machinery is critical to production or operations.

6. Evaluate Costs and Transparency

While cost should not be the sole deciding factor, it is an essential consideration. Ensure that the hydraulic repair service offers competitive pricing without compromising on quality. Look for services that provide clear and transparent quotes.

- Upfront Pricing: A reputable company will provide an accurate estimate of costs before beginning any work, helping you avoid surprise charges.

- Cost-Effectiveness: While inexpensive repairs may seem appealing, they can often result in subpar work and recurring issues. Focus on finding a service that balances cost with quality.

7. Check for Custom Solutions

Every industry has unique hydraulic system needs. The best repair services will be able to offer custom solutions tailored to your specific machinery. Whether it’s specialized components, unique machinery configurations, or specific operational requirements, a repair service that can offer personalized solutions will help keep your equipment running at peak efficiency.

Conclusion

Choosing the right industrial hydraulic repair service is an important decision that directly impacts the performance and longevity of your machinery. By evaluating a company’s expertise, range of services, reputation, response time, and cost transparency, you can ensure that your hydraulic systems are in the best hands. With the right repair service, you can maintain the efficiency and reliability of your machinery, minimize downtime, and avoid costly repairs in the future.